Advantages and maintenance of automatic feeder for chicken farming equipment

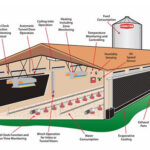

The automatic feeder in poultry farming equipment is the equipment that every large and medium-sized farm should have to feed chicken houses. The automatic feeder has a high degree of automation, is convenient for energy saving, has a short feeding time, and does not require a lot of personnel. It only needs to set a small time for feeding, which is very convenient. However, farmers should also pay attention to maintenance when they use automatic feeders, so that they can use longer. The author will talk about the advantages and maintenance of automatic feeder.

First, the advantages of automatic feeder:

The transmission of the automatic feeder is smooth and uniform, so that the entire machine can be evenly fed. The automatic feeder uses a uniform feeding device. The feed can be evenly distributed to the trough through the feeding tube through gravity. This can avoid the spillage of manual feeding and save the feed. It can also save labor, this machine is a single feeding of the vehicle, and its operation is five minutes to eight minutes.

Second, the maintenance of automatic feeder:

1. When the automatic feeder is started, it is best not to put anything on it. Putting things on it will easily cause the motor to bear too much pressure and it will burn out the motor. Check if its belt is intact and loose. The automatic feeder is used to transport materials by leather belts. Only when the belt is normal can the machine’s production performance be fully exerted and its workload can be maximized.

2. Because the various parts of the automatic feeder are controlled by gears and chains, it is necessary to ensure the maximum lubrication of the gears and the chain. Only in this way will the machine be damaged due to lack of lubrication.

3. The automatic feeder will produce a lot of dust during the production, which will cause a large amount of dust to accumulate in the control box of the automatic feeder. A large amount of dust will short-circuit the internal circuit and damage the electrical circuits and other components, so be sure to clean the dust in the control box every once in a while.

4. The main power of the automatic feeder comes from the motor. The motor is divided into a power motor and a reduction motor. Since the speed of the motor is very high, a geared motor is used to reduce the speed when transmitting power. When using chicken equipment accessories, be sure to check the power motor and gear motor for abnormalities. The motor also needs maintenance, such as adding gear oil to the gear of the reducer.

The above is the author’s description of the maintenance method of the automatic feeder when using the automatic laying hen cages and the broiler cage.