How should the layer rearing equipment be selected?

Recently, there are several customers who are cultivating laying hens. When consulting products, it is contradictory to choose whether the equipment is stepped or stacked. I don’t know how to choose. Based on years of experience, the author will introduce to you how to make decisions on the selection of layer rearing equipment.

First of all, let me introduce to you now there are two mainstream poultry farming equipment for laying hens, one is stepped and the other is cascading. Now both devices can be fully automated, including feeding, drinking, cleaning, collecting eggs and ventilation. They can be very advanced, which can reduce the labor intensity of workers and save labor costs.

Stepped layer rearing equipment

The stepped hen equipment is the A-type installation of the chicken cage. There are two kinds of faeces, such as scraper and manure, which are relatively early use of laying hens. Nowadays, small and medium-sized customers still use ladder-type layer rearing equipment.

Its advantages are:

1. The open area of the chicken cages in each layer is large, even if it is the open style chicken house, the ventilation is just as good;

2. The lighting is better, and natural light can be used;

Its shortcomings are also obvious;

1. Low stocking density and large land occupation;

2. The chicken manure on the upper layer of the chicken cage will fall to the lower layer of chicken.

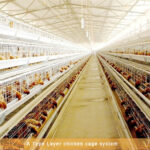

The battery poultry farming equipment means that the chicken cages are layered like a building. This kind of equipment was developed later. Due to the increasingly tight land resources, the land that can be used for farming is becoming less and less. Therefore, more and more customers will increase the density of breeding, in order to save land. Modern laying hens are becoming more and more intensive, some even 8-10 layers, and 100,000 chickens in a chicken house.

Its advantages are:

1. Achieve full automation control, greatly reducing the number of operators, reducing labor intensity and improving labor productivity;

2. There is a clearing belt at the bottom of each layer, which is clean and hygienic to ensure the health of the chicken;

3. Small footprint, high space utilization, easy to achieve intensive and large-scale breeding;

4. The chicken manure is layered and cleaned, and it is easy to collect and concentrate after treatment. The utilization rate of chicken manure is high and the pollution to the environment is extremely small;

5. The fully enclosed feeding mode is conducive to preventing the occurrence of infectious diseases and improving the production performance of the flocks.

Its shortcomings:

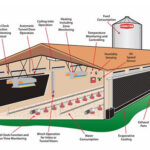

1. It is necessary to adopt closed type and automatic temperature control, otherwise the temperature inside the house is difficult to control;

2. The risk factor is relatively high, and there are tens of thousands of chickens in a house.

Personally, if the laying rate of laying hens is less than 30,000, it is better to choose a step type. If the laying rate of laying hens is more than 50,000, it is more appropriate to choose a battery type.